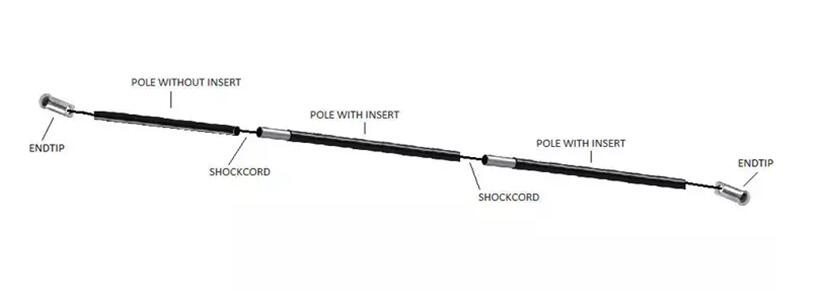

There are 2 types of 7000 series durable anodized aluminum tent pole:

(1) Poles with inserts -the insert is a tube (or sleeve) that is typically glued inside one hollow end of a tent pole section and protrudes approximately 3". This insert allows you to stack one section on top of another.

(2) Poles without inserts-these are hollow poles (sections) with no inserts

To make a set of poles it is usually best to map out on paper to determine how many sections and parts you many need of each. You will usually need more sections with an insert than those without. For example if you want to make a pole with 4 sections (this would make a 6 foot long pole), you would need to have 3 sections with an insert and 1 without an insert. The reason you need the last section to be without an insert: picture stacking one section with an insert on top of another. If the last section has an insert, that would not allow you to put an endtip into both ends of the pole. Therefore if you use a section without an insert for the last one you will have a hollow end on both ends of the pole, this allows you to put an endtip on each end of your pole.

HOW TO MAKE 7000 series durable anodized aluminum tent pole:

Step #1 Lay out your poles in the order you want them. (cut them to the right length, if it is necessary, using a hacksaw or even better a pipe cutter (we stock these for your convenience). Note: If you need to shorten carbon fiber poles wrap the pole with tape over the area that needs to be cut to keep it from fraying.Step #2 Knot one of the endtips onto to one free end of the shock cord and push it into one of the hollow ends of the pole sections. Thread your shock cord through each pole section.

Step #3 On the other end, tie the other endtip onto the shock cord. Push the second endtip up into the other hollow end of the pole. Test the tension; you do not want it too tight that when they are folded up they want to spring open. If the tension needs to be re-adjusted, re-tie the knot. If the shock cord is not tight enough remove the end tip and re-tie it a little tighter.